Niaux200

The World Famous

Published on July 26, 2023

French Disc

| The agricultural industry is constantly evolving, with farmers continually seeking solutions to increase their productivity while reducing maintenance costs. In this context, wear parts play a crucial role as they undergo significant stresses during soil work. This is where FORGES DE NIAUX, the renowned French manufacturer, comes into play with its latest innovations – the NIAUX 200 agricultural discs. These revolutionary components push the boundaries of premium quality and meet the needs of farmers worldwide. |

A Legacy of InnovationFORGES DE NIAUX is a company that has left its mark on the history of agriculture for decades. Their commitment to innovation and premium quality has given birth to iconic products such as the « NIAUX 140 » disc in the 1960s and the « NIAUX 160 » in the 1980s. Today, they are taking a crucial step by launching the NIAUX 200, a wear part that is revolutionizing the agricultural sector. The numbers 140, 160, and 200 correspond to the hardness of the steel applied to the agricultural discs, measured in kg/mm2. The higher the hardness, the more resistant the disc will be to wear. However, nowadays, it is more accurate to measure hardness in Rockwell (HRC): |

| CONVERSION TABLE | |

| kg/mm2 | HRC |

| 140 | 43 |

| 160 | 48 |

| 200 | 55 |

| 220 | 58 |

Objective: To Resist against Wear, Breakage and DeformationAs we have seen in previous articles, agricultural discs must meet certain mechanical constraints to ensure their agronomic functions:

It is important to remember a key principle about wear on wear parts used for soil preparation: |

variation in wear = ( variation in speed ) 2 |

|

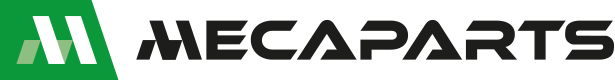

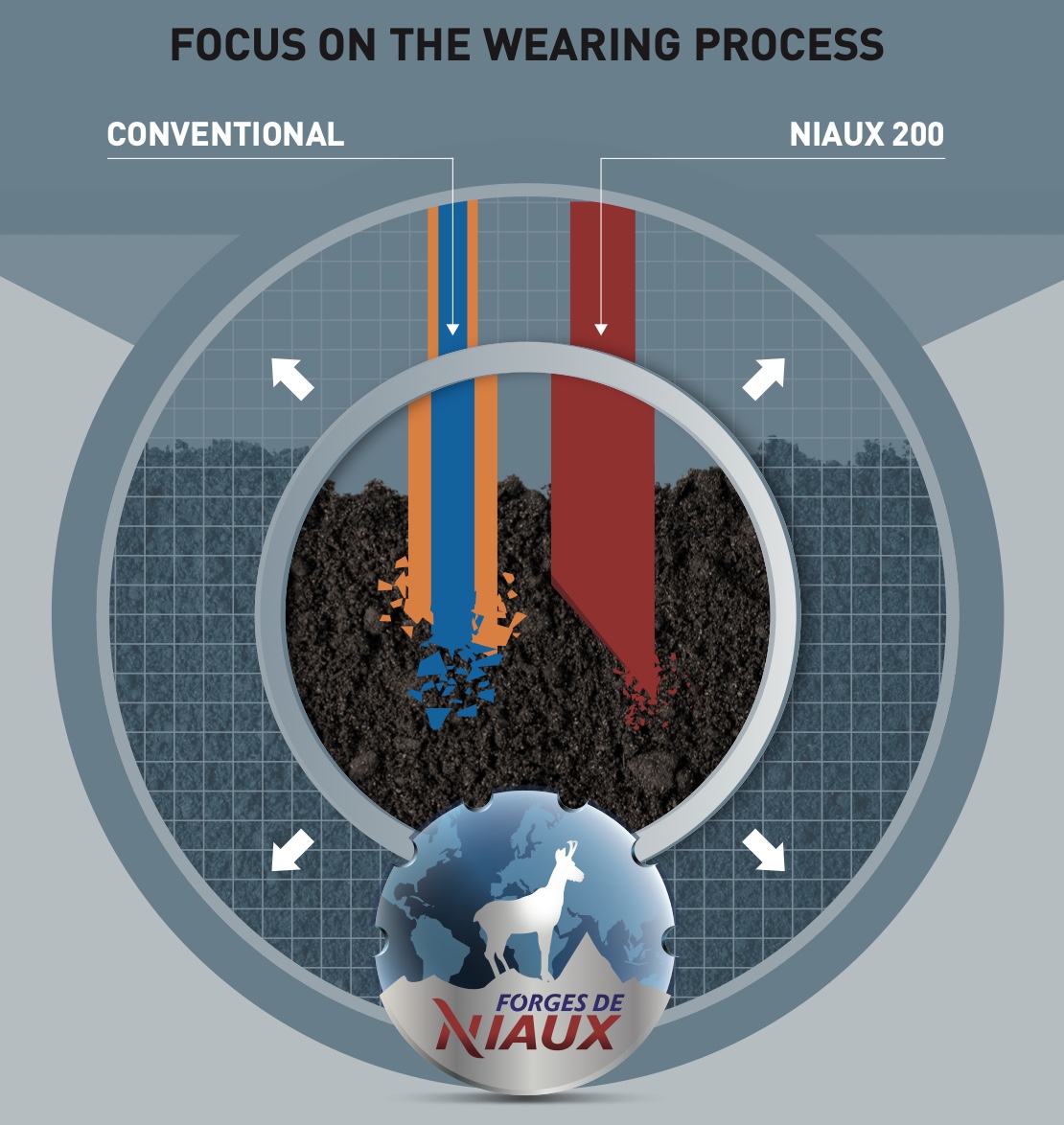

The faster you go, the faster the wear speed of the parts will accelerate. With the increase in tractor power and, consequently, traction speeds, wear on parts has significantly increased in recent years. In order to resist wear, manufacturers of soil working parts seek to increase the hardness of the steel using heat treatment. However, increasing hardness while maintaining the bending capabilities and resistance to breakage of the parts is a real metallurgical challenge. When a disc absorbs an impact (rocks, stumps, etc.), the bending exerted creates high pressure on the central part of the disc. It is therefore important to give this area a greater shock absorption capacity. The main problem that disc manufacturers had to deal with was the hardness limit that could be applied to the center of the disc. If it exceeded 50 HRC, the risk of breakage was greatly increased. The “classic” manufacturing process involved achieving a uniform hardness across the entire disc, the maximum hardness achieved by manufacturers was 50 HRC. It is to address this issue that the NIAUX 200 manufacturing process provides a solution. It consists of applying different hardness levels to different zones of the disc using heat treatment. |

Zones of Niaux200 Disc Blade

|

| All NIAUX 200 productions must successfully withstand 400 bending cycles without breaking before they are shipped to customers. As we can see in this video, the force applied to the center of the disc is very significant, and the discs must have a high bending capacity to avoid breakage |

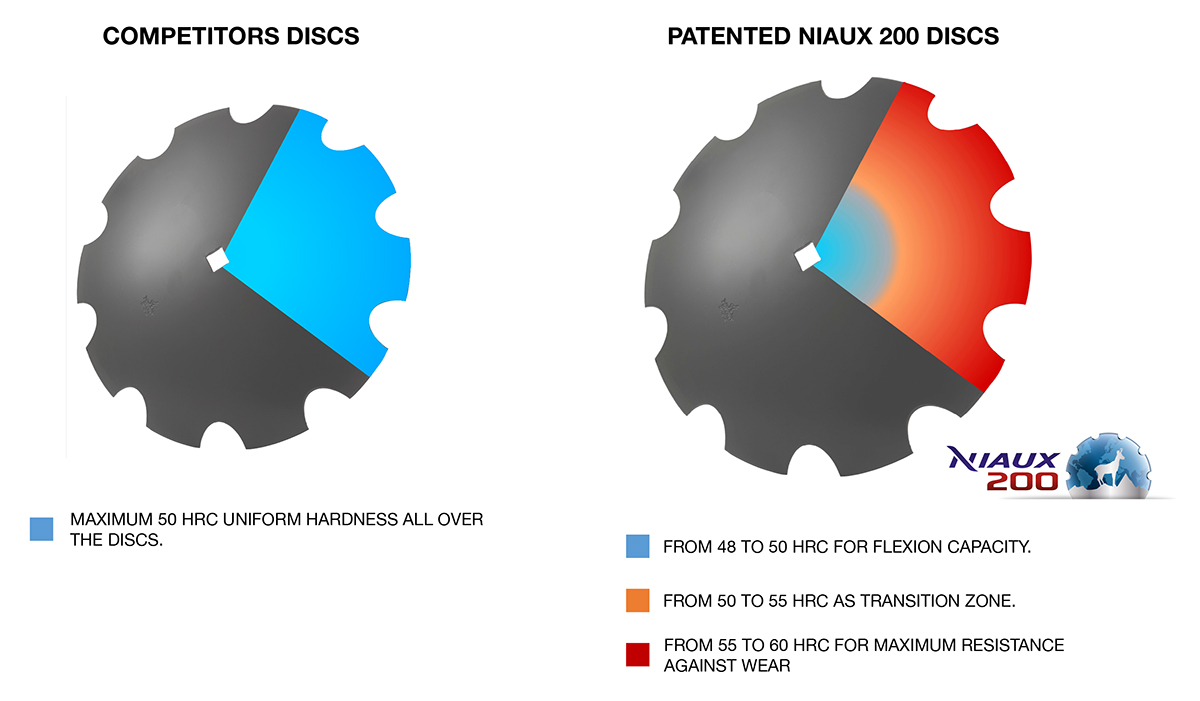

The auto-sharpening disc bladeNIAUX 200 is a quality that offers an additional advantage in terms of cutting durability. Thanks to its heat treatment throughout the thickness of the disc, the discs stay sharp for a longer time compared to competing qualities. In fact, competing parts typically have surface hardness only, which leads to a tendency for the bevel of the discs to round off more quickly, making them less sharp. As a result, NIAUX 200 provides better cutting longevity, allowing for optimal cutting performance over a longer period without frequent disc replacement |

A Game-Changer for FarmersIn the fast-paced world of agriculture, where every hour and every hectare count, FORGES DE NIAUX’s NIAUX 200 agricultural discs are nothing short of a game-changer. These discs are not just equipment; they’re a revolution in farming. So, if you’re a farmer looking to boost your productivity, cut costs, and get the job done right, look no further than the NIAUX 200. It’s not just a disc; it’s a farming revolution in your hands. Say goodbye to downtime and hello to higher yield. Your fields will thank you. |