Guideline for Coulter Blades in Modern Farming

Published on October 5, 2023

Coulter blades, an ancient agricultural tool, have evolved into a crucial component of contemporary farming, offering a wide range of applications. Selecting the right coulter blade for your equipment and soil type is vital for optimal results. In this concise guide, we’ll explore the basics of coulter blades, their functions, types, benefits for soil health, and key considerations when choosing and maintaining them.

What Is a Coulter Blade?A coulter blade is a rolling cutting tool primarily used in tillage implements, planters, and seeders. Its primary function is to break and soften soil before secondary tools like plowshares, disc blades, fertilizer knives, and seed openers take action. Why Do Farmers Use Coulter Blades?Farmers use coulter blades to improve soil conditions by breaking up heavy, compacted, or crusty soil. The benefits include reduced drag, faster plowing, consistent blade penetration, neater furrows, lower fuel consumption, and cost savings. |

Main Types of Coulter BladesCoulter blades have evolved from fixed vertical blades to rolling discs with various profiles. Smooth Coulter Blades: Ideal for residue management and soil refinement with minimal soil disturbance. |

| Notched Coulter Blades: Provide excellent grip in heavy soil and high debris conditions. |

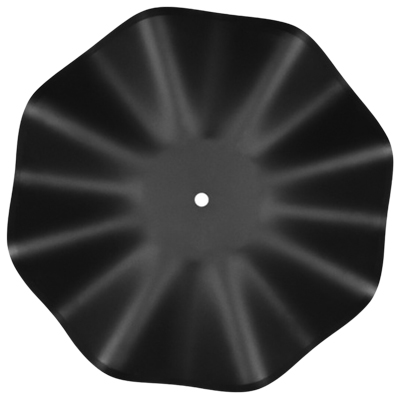

| Wavy Coulter Blades: Offer aggressive soil movement for residue management and excellent tilling action in almost any soil conditions. |

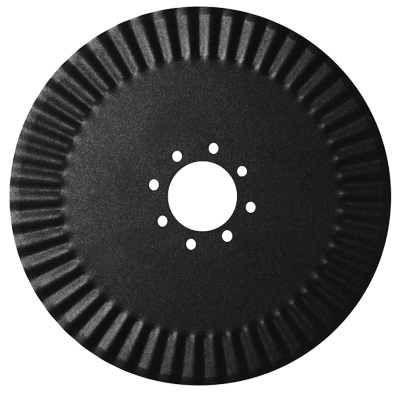

| Fluted Coulter Blades: Achieve depth without significant lateral soil movement. |

| Directional Coulter Blades: Provide an aggressive cutting action with minimal soil movement. |

Benefits for Soil HealthCoulter blades contribute to soil health by facilitating weed control, residue management, enhanced moisture absorption, improved soil aeration, and optimal seed placement. They create a conducive environment for crop growth and yield. Key Considerations When Choosing Coulter BladesMaterial: Coulter blades are typically made of steel, with variations in hardness and durability. Boron steel is preferred for its exceptional hardness and wear resistance. Profile: Consider blade concavity for soil movement and residue management. Dished blades move more soil, while flat blades offer powerful vertical tillage for residue control. Bolt Pattern: Ensure the bolt pattern matches your equipment specifications for proper installation. Maintaining Coulter BladesProper installation and maintenance are essential for peak performance. Ensure blades are securely fitted, set at the correct depth and angle, and that bearings are in good condition and well-greased. Regularly inspect blades for wear and replace them when they lose an inch of their original diameter. Want to know more?MECAPARTS offers a complete range of aftermarket coulter blades to fit all popular plow and cultivator brands. To find out more about our product range, contact us info@mecapartsinternational.com or visit our website www.mecapartsinternational.com |